In the dynamic world of packaging, where the safety and integrity of goods during transit are paramount, the role of effective packaging materials cannot be overstated. Among the plethora of options available, the packaging foam roll emerges as a versatile and reliable choice, providing cushioning and protection for a wide range of products.

From fragile electronics to delicate glassware, the packaging foam roll proves its mettle in safeguarding items from the rigors of transportation. In this article, we will delve into the various ingenious ways you can harness the potential of a packaging foam roll to ensure your shipments reach their destination unscathed.

Furthermore, we'll explore an innovative alternative—air column packaging—that stands out as a commendable substitute to traditional packaging foam, offering a new dimension to the realm of secure shipping. Let's unravel the best practices and discover how these packaging solutions can revolutionize your shipping experience.

What Are Packaging Foam Rolls

Packaging Foam rolls are continuous sheets of foam material wound into rolls for packaging purposes. These rolls are commonly used in various industries for protecting items during shipping, storage, or transit. The foam material is typically lightweight, flexible, and offers excellent cushioning properties, making it an ideal choice for safeguarding items against scratches, impacts, and other potential damages.

Best Ways To Use a Packaging Foam Rolls

Here are some of the best ways to use packaging foam rolls:

-

1. Wrap and Protect Fragile Items

Packaging foam rolls can be used to wrap and protect fragile items. When safeguarding delicate items in transit, they prove to be an invaluable asset. The continuous sheet of foam can be expertly wrapped around these items, forming a protective cushion that absorbs impacts and minimizes the risk of damage during transportation.

The beauty of using foam rolls lies in their ability to conform to the contours of each item, ensuring a snug fit in the desired shape. This tailored approach enhances the protective barrier, leaving no room for unnecessary movement or contact. The result is a secure, cushioned layer that acts as a shield, safeguarding fragile items against the unpredictable rigors of transportation.

-

2. Customized Padding for Large Items

Foam rolls can also be used as customized padding for large items. Large items, such as appliances or oversized electronic equipment, often pose a challenge when it comes to finding adequate packaging solutions. Cutting foam rolls into sections enables the crafting of customized padding that perfectly matches the size and shape of the large items. This tailored approach not only ensures a secure fit but also provides a substantial protective layer against scratches and abrasions.

-

3. Void Filling and Dividers

One of more best ways to use foam rolls is void filling and dividers. In the intricate world of packaging, where every inch of space matters, the strategic use of foam rolls extends beyond merely wrapping individual items. By cutting smaller sections of foam wrap rolls, you unlock a versatile solution for two critical functions: void filling and creating dividers.

When items are placed within a shipping box or container, there's often empty space between them. This void can lead to movement and shifting during transportation, which, in turn, increases the risk of breakage. Enter foam rolls. By cutting smaller sections and strategically placing them within these voids, you create a buffering layer that minimizes movement.

In scenarios where items of different shapes, sizes, or fragilities are packed together, creating dividers becomes a strategic necessity. By carefully cutting and placing foam sections, you create individual compartments within the packaging. Each compartment acts as a protective barrier, preventing direct contact between items.

-

4. Cushioning for Sensitive Surfaces

Certain items, especially those with sensitive surfaces, demand an extra layer of care during packaging. Foam rolls excel in providing cushioning for these delicate surfaces, ensuring they remain unscathed during transportation.

By carefully wrapping items with sensitive surfaces in foam wrap, you create a protective barrier that absorbs shocks and impacts. This is particularly relevant for items with finishes, screens, or surfaces prone to scratches or damage from contact with other objects. The foam acts as a cushion that absorbs the force of any external impact, minimizing the risk of surface damage.

-

5. Secure Packaging for Irregular Shapes

The challenges of packaging are often magnified when dealing with irregularly shaped items, where standard packaging solutions may fall short. In such scenarios, the packaging foam roll can be used to wrap items. The flexible and adaptive nature of foam packaging rolls offers an ideal solution for ensuring the secure transit of items with unique contours.

-

6. Enhance Box Integrity

Ensuring the structural integrity of shipping boxes is paramount when it comes to safeguarding the contents during transit. One effective method to fortify the box's strength is by lining its interior with foam rolls. This additional layer of reinforcement not only provides support to the box itself but also contributes significantly to the protection of the items within.

-

7. Combine with Other Packaging Materials

In the quest for a robust and comprehensive protective packaging solution, the strategic integration of foam rolls with other packaging materials proves to be a winning strategy. This approach allows for the creation of a multi-layered defense system, combining the unique strengths of various materials to provide enhanced protection for shipped items.

Air Column Packaging: A Sustainable Alternative to Foam Roll

In the realm of packaging solutions, the Air Column packaging stands out as a novel and eco-friendly alternative to traditional foam. Unlike other forms of packaging materials, the Air Column packaging offers a range of advantages, making it an excellent choice for those seeking efficient and sustainable packaging options.

Space-Saving and Cost-Effective

Air Column packaging is a space-saving marvel, lying completely flat before inflation. This flatness optimizes storage space, reducing the required storage footprint compared to bulkier foam rolls. Additionally, their cost-effectiveness makes them an attractive choice for businesses looking to balance quality protection with cost efficiency.

Water and Shock Resistance

A notable feature of Air Column packaging is its resilience. It boasts water-resistant properties, ensuring protection against moisture during transit. Furthermore, its shock resistance capability shields items from impacts, maintaining the integrity of the packaged goods.

User-Friendly and Versatile

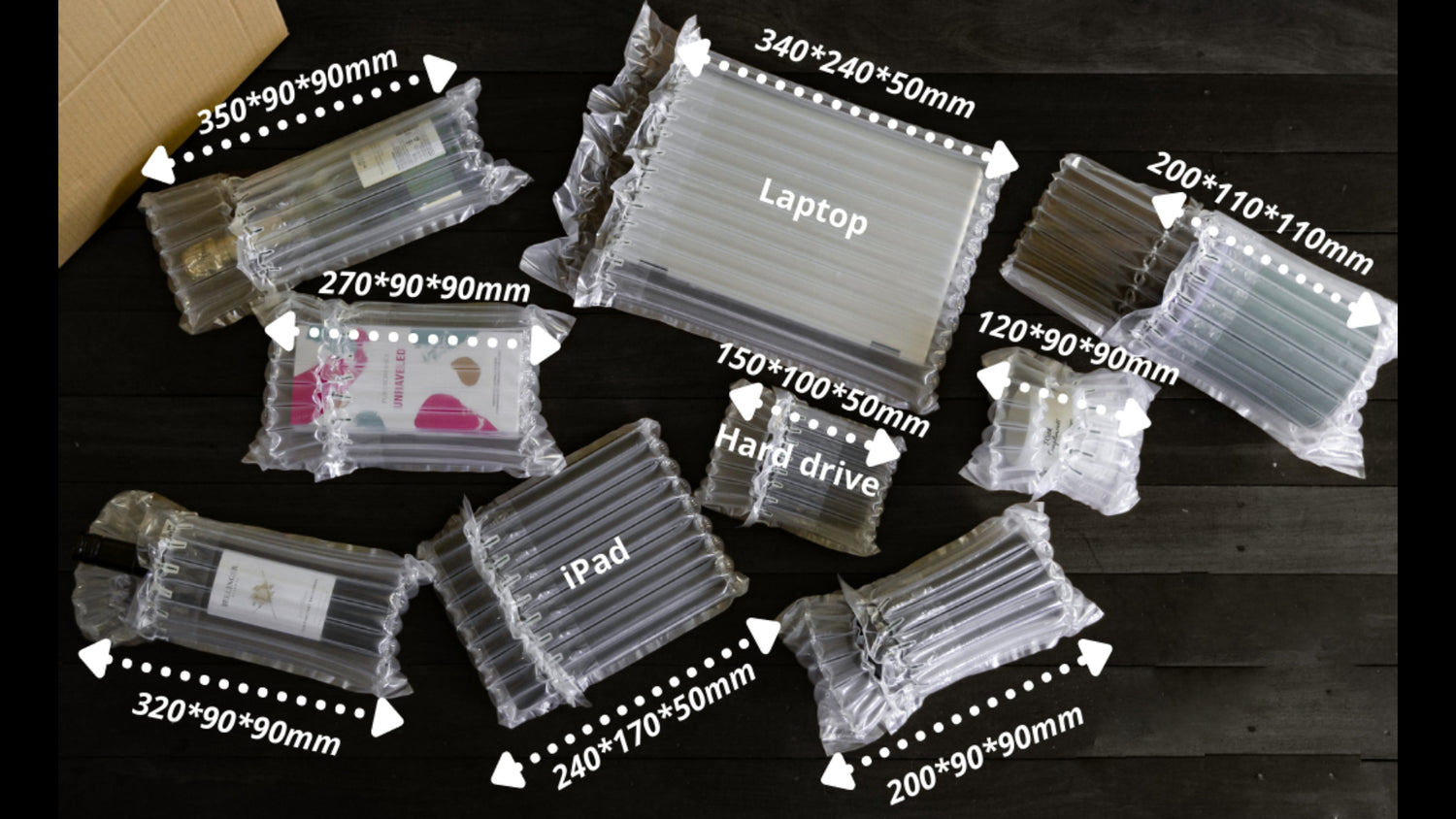

The Air Column packaging is designed with user convenience in mind. Its user-friendly nature makes it easy to handle and deploy, streamlining the packaging process. Moreover, its versatility allows for various shapes and types, providing tailored protection for different items.

Enhanced Product Protection

Utilizing multiple independent air columns, these packaging offer a high level of product protection. In a unique design, adjoining air columns remain securely inflated even if one column is punctured. This ensures continued protection for the packaged items throughout the shipping process.

Technology Behind the Design

The Air Column packaging consists of two layers of PE films with an air valve film in between. Heat pressing these layers together creates air columns and shapes, allowing for a variety of customizable styles. This innovative construction ensures durability and resilience.

Variety of Air Column Types

Within the realm of Air Column Packaging, there are diverse options tailored to specific needs. For instance, the Mini Air Wrapper V comprises mini air tubes made with PE+nylon material, providing excellent cushion protection without air leaking. Similarly, the Mini Air JifBag, akin to a bubble mailer, inflates automatically, saving labor, storage space, and increasing efficiency.

In essence, Air Column Packaging represents a sustainable and efficient evolution in packaging materials.

Conclusion

In a world where protecting shipped goods is crucial, foam rolls stand as versatile guardians. From tailored cushioning for fragile items to reinforcing box integrity, their adaptability can be used in many best ways. However, the emergence of Air Column packaging as a sustainable alternative heralds a new era. With its space-saving design, resistance to shocks and water, and versatile applications, it signifies a promising evolution in packaging solutions.

FAQs

What is the difference between packing foam and poly foam?

"Packing foam" is a general term encompassing various packaging materials, while "poly foam" specifically refers to foam made from polyethylene. Poly foam, chemically inert and non-abrasive, is often utilized for surface protection due to its cushioning properties.

Can I request a specific thickness for packing foam rolls?

Yes, packing foam rolls are available in various thicknesses to suit diverse packaging needs. Whether you need 2mm x 100m rolls or other dimensions, you can request a specific thickness based on your requirements.

Can I use anti-static foam rolls for packaging delicate electronic items?

Yes, anti-static foam rolls are specifically designed to protect delicate electronic items from static electricity. The foam's cushioning properties safeguard against shocks, ensuring the safe transit of electronics. When ordering, inquire about shipping costs and explore options for fast delivery to meet your packaging timeline.